Lifting & Engineering Division

Tech North and associated companies have been dealing with the mining sector for 50 years. The Steelpoort branch are leaders in the service and supplies of the following:

Fluid sealing systems

Vibratory screening products

All types of hoses

Bulk mining consumables

Compensators

Expansion joints

A large range of valves and tools

Pump repairs – vertical spindles, submersibles pump

Stihl – Repairs on all Stihl products

Repair of all tensioners, croppers , hand pumps & hydraulic air pumps

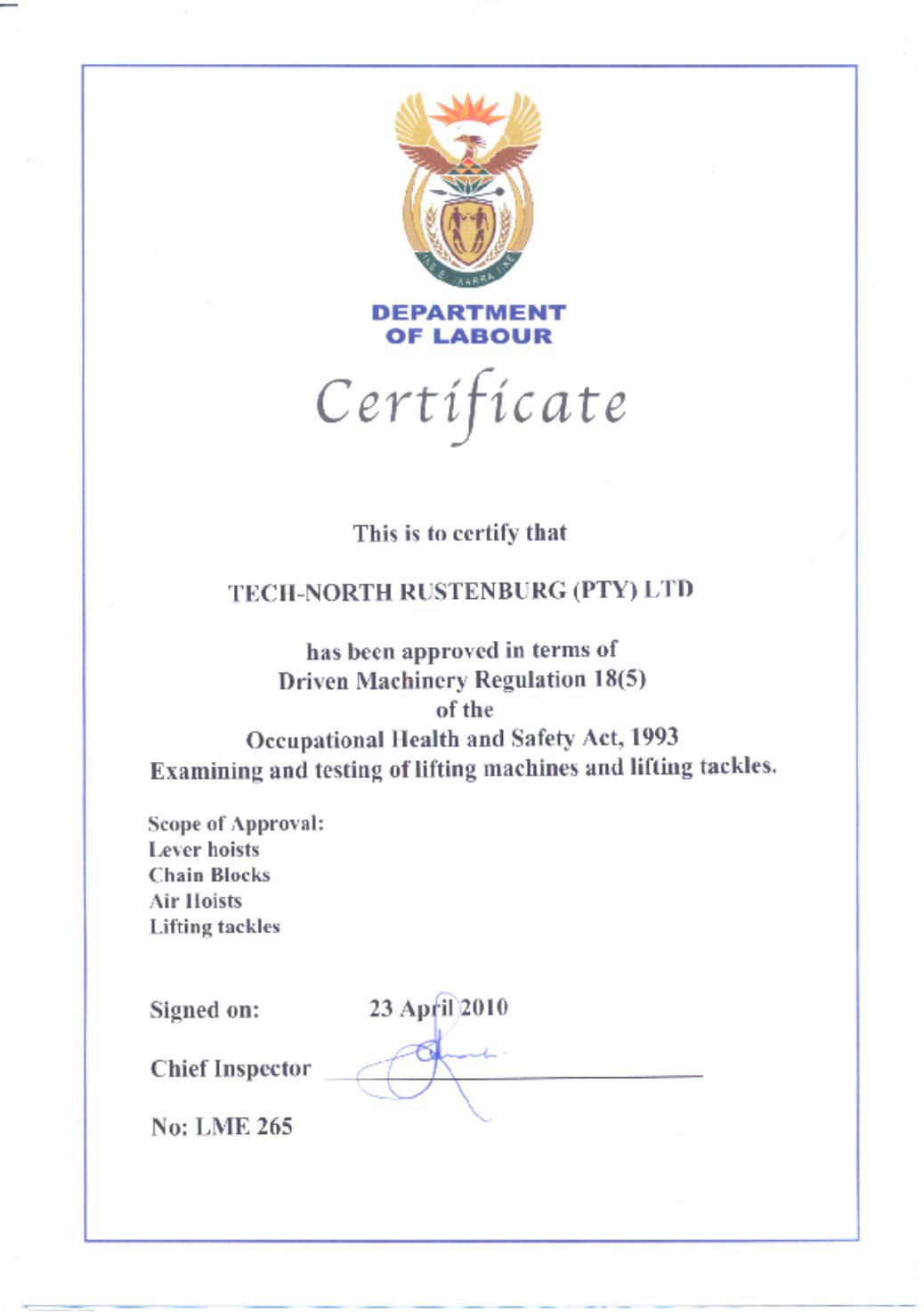

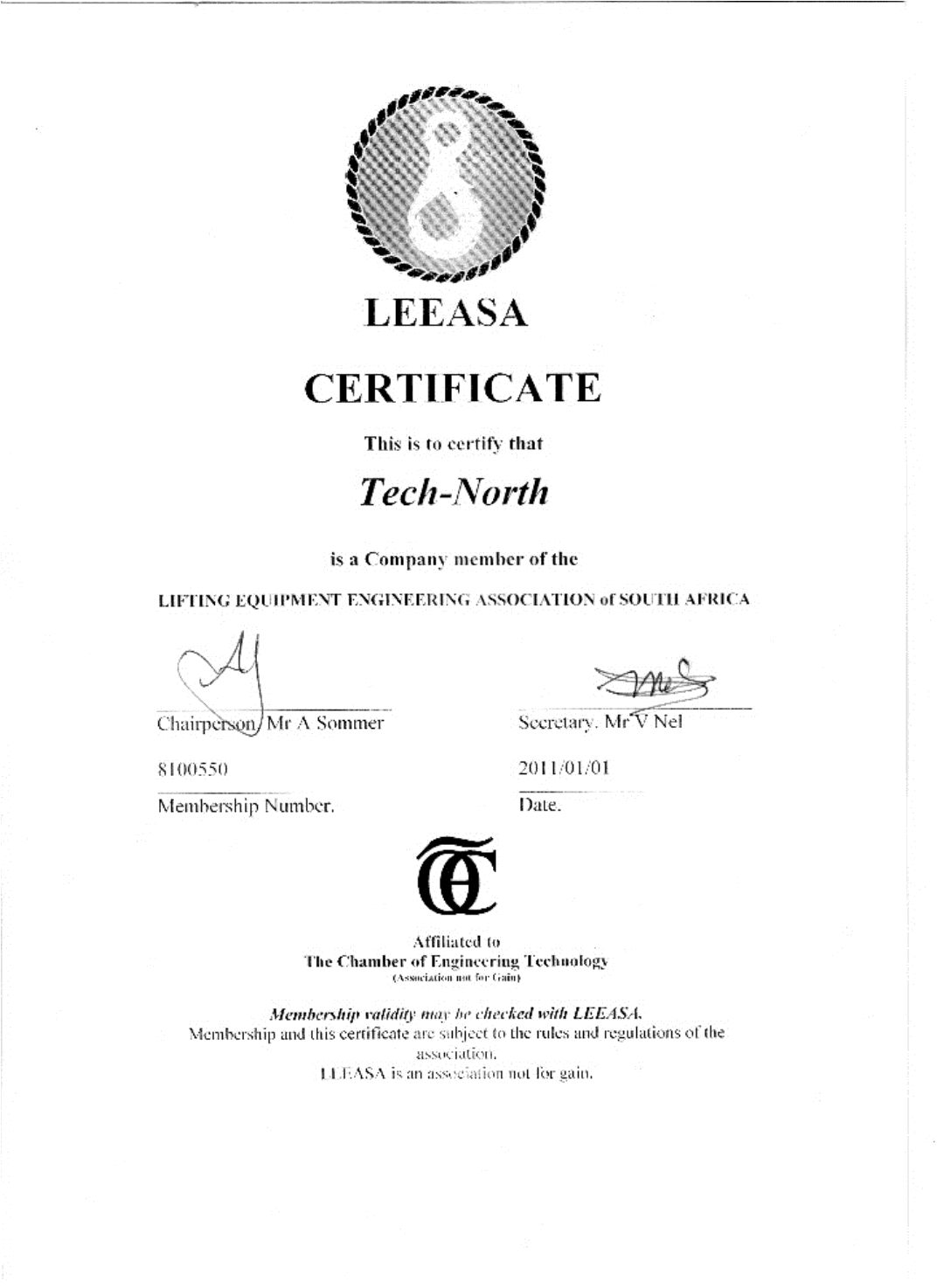

Accreditation & Appointments:

The company is accredited and registered as an LME with the Dept. of Labour in accordance with the Occupational Health and Safety act. LME no. 436

LMI – The company has assigned Hennie Dreyer as Lifting Machinery Inspector to implement and maintain a full traceability system as prescribed in the OHS act and the SANS standards. He is registered with the Engineering Council of SA – LMI 201612017. Lifting and Rigging experience 10 years.

LTI – Dawid Nkosi is assigned as Lifting Tackle Inspectors to execute on site inspections, on quarterly and bi-annual basis as required in the OHS act.

Workshop – Hennie runs the workshop as LMI, Qualified Fitter & Turner workshop manager.

We are Distributors of the Following International Companies:

Klinger Mzanzi– All gaskets & gland packing

AESSEAL – Mechanical seals & bearing associates

Anchor Industries – Titan chain blocks, lever hoists, tackle, and associated rigging gear

KITO Lifting – Kito chain blocks, lever hoists, electric hoists and associated rigging gear

BELZONA – Specialized maintenance & repair products as well as specialized coatings with our own application crews

RCM plastics – Polyurethane panels & vibratory motors

Insamcor – Valves

Stihl – Chainsaws & Brushcutters

We Offer the Following:

Safe Lifting Program

Tech North offers a Safe Lifting Program to help companies and individuals comply with legal requirements. As an independent party, we take on a significant portion of this responsibility.

On-Site Inspections & Load Testing

Using our mobile rig, we conduct on-site load testing and certification—quarterly for tackle and bi-annually for lifting machinery. All details are carefully recorded and filed for traceability. Minor repairs can be carried out on-site, while failed units will be marked with a red tag indicating: “FAILED – Do Not Use.”

Beam Load Testing

Our stationary test rig is engineered and certified to withstand up to 20 tons, utilizing dead-weight for optimal dynamic test results. Meanwhile, our mobile test rig features a hydraulic cylinder and pump, allowing for both dynamic and static testing of loads up to 10 tons.

Important Reminder: Traceability is Crucial for Safe Lifting

All details, tasks performed, and findings are carefully recorded on a job card and securely filed for five years in compliance with OHS and SANS regulations.